Discovering the Principles of Welding Examination: A Thorough Examination of Procedures, Devices, and the Value of Quality Assurance in Welding Industries

Welding assessment serves as a keystone in the maintenance of safety and security and architectural honesty throughout various sectors. By checking out the crucial procedures and tools utilized in these examinations, one can appreciate the intricate balance between quality control and conformity with well-known requirements from organizations such as AWS and ANSI. The approaches used, consisting of non-destructive and visual testing techniques, are crucial in finding flaws that could compromise the sturdiness of bonded frameworks. Comprehending the effects of these methods increases important questions concerning their efficiency and the future instructions of quality control in welding.

Importance of Welding Examination

Welding examination plays an essential duty in guaranteeing the integrity and security of bonded frameworks. It offers as a systematic technique to reviewing weld quality, determining potential defects, and guaranteeing conformity with well established criteria and specifications. The significance of welding inspection prolongs past plain adherence to laws; it is pivotal in safeguarding human lives and safeguarding financial investments in infrastructure.

Malfunctioning welds can cause disastrous failings, leading to substantial financial losses, injury, or loss of life. For that reason, strenuous examination processes are necessary to identify concerns such as poor penetration, porosity, or cracks before they rise right into important failings. Furthermore, effective welding examination adds to the overall performance and longevity of frameworks, making certain that they can hold up against the conditions for which they were made.

Furthermore, the implementation of welding examination cultivates a culture of quality and liability within the welding sector. By prioritizing evaluation, organizations demonstrate their dedication to excellence, thereby boosting their track record and competition in the industry. Eventually, welding inspection is not just a step-by-step step however a fundamental element of engineering integrity and safety and security assurance, essential for the successful implementation of welding jobs throughout different fields.

Key Examination Processes

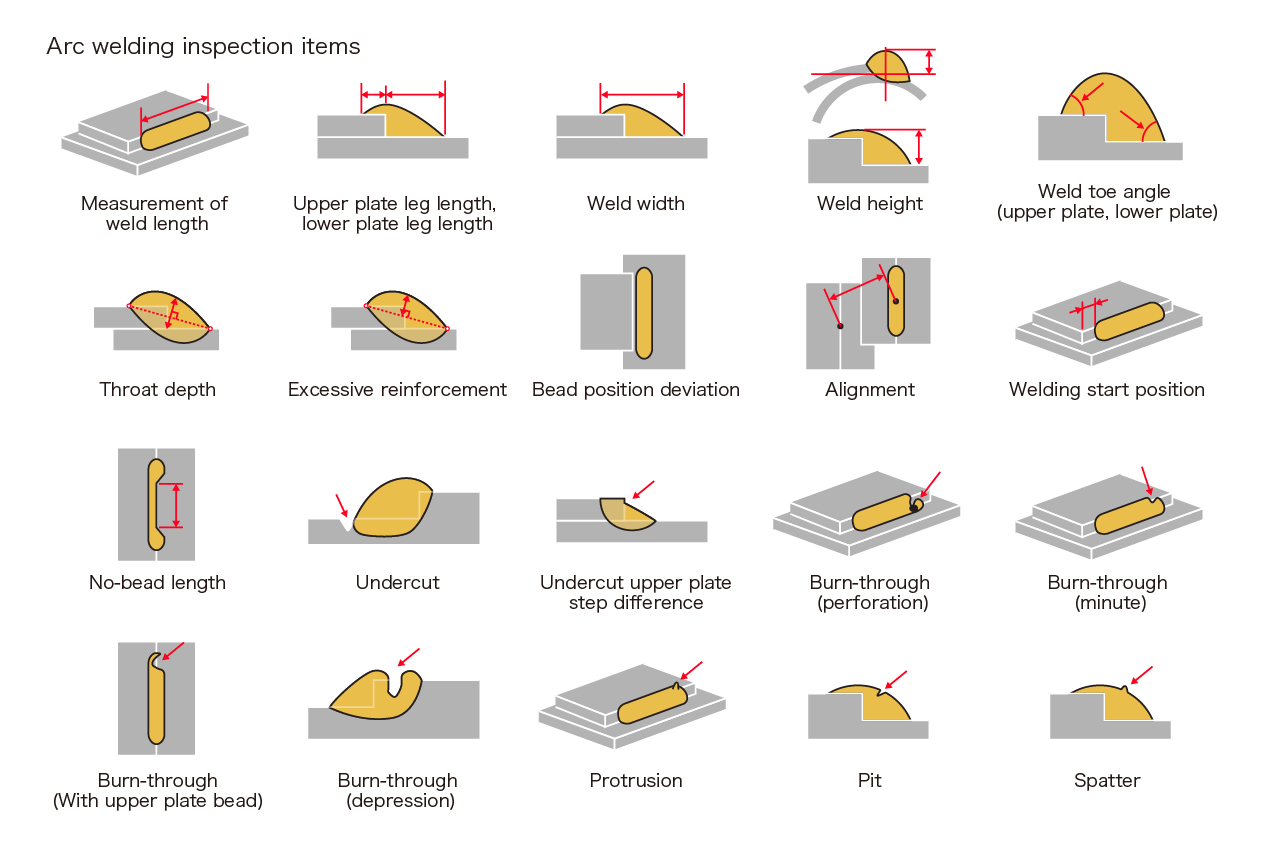

A thorough method to welding examination involves a number of vital processes that are essential for making certain weld high quality and structural honesty. The first important process is visual assessment, which allows examiners to recognize surface area problems such as fractures, porosity, and inappropriate bead look. This method offers as an initial assessment to make sure that the weld fulfills defined criteria.

In addition, devastating screening may be performed on sample welds to assess their mechanical residential or commercial properties and performance under tension. This process involves influence, tensile, and exhaustion screening to verify that the weld can endure operational conditions.

Last but not least, paperwork and reporting are important elements of the evaluation procedure. Keeping exact documents of examinations, observations, and examination results helps guarantee compliance with sector requirements and promotes continual renovation in welding methods. Collectively, these vital procedures form the foundation of effective welding inspection and quality control.

Tools for Weld Analysis

Various devices are necessary for effective weld analysis, each created to evaluate various elements of weld top quality and performance. Amongst the most commonly made use of are visual inspection devices, consisting of magnifying glasses and borescopes, which allow assessors to recognize surface area problems such as splits, porosity, and inappropriate blend.

In addition, ultrasonic testing (UT) devices is crucial for click to investigate detecting inner flaws. This tool utilizes high-frequency audio waves to reveal stoppages within the weld, guaranteeing the stability of the product. Radiographic testing (RT) tools, which use X-rays or gamma rays, in a similar way offer understanding right into the inner framework of welds, enabling the recognition of voids or inclusions.

For specific measurements, calipers and evaluates play a substantial role in figuring out weld measurements and making certain adherence to specified tolerances. Firmness testers review the mechanical buildings of the weld, guaranteeing it meets performance standards.

Methods for Evaluating Quality

Exactly how can the quality of welds be accurately examined? A variety of methods are employed to examine weld integrity and make sure adherence to specified criteria.

Ultrasonic testing (UT) is an additional popular strategy that uses high-frequency audio waves to spot inner flaws within the weld. Houston Welding Inspection. This approach provides a thorough view of the weld's stability without compromising its structural honesty. In addition, radiographic testing (RT) uses X-rays or gamma rays to reveal interior problems, supplying comprehensive understandings right into weld quality

Magnetic bit screening (MT) is efficient for identifying surface click over here area and near-surface interruptions in ferromagnetic materials, making use of electromagnetic fields and tinted particles to highlight problems. Color penetrant testing (PT) can be used to discover surface-breaking defects by using a color that leaks right into splits and is consequently exposed.

Compliance With Sector Standards

Compliance with industry requirements is crucial for making certain the quality and safety of bonded frameworks. These standards, established by companies such as the American Welding Society (AWS) and the American National Specification Institute (ANSI), give standards that govern the welding procedure, products, and inspection protocols. Following these criteria not just guarantees the structural stability of welds however additionally alleviates threats connected with failures that could result in devastating consequences.

Welding examiners are entrusted with verifying conformity with these criteria throughout the welding process (Houston Welding Inspection). This involves assessing welding treatments, checking welder certifications, and conducting comprehensive inspections of the final product. Non-compliance can result in substantial monetary repercussions, task delays, and damages to a company's online reputation

Normal training and updates on standards are crucial to keep workers educated and proficient, making certain that all aspects of welding operations satisfy or surpass governing requirements. Eventually, commitment to industry criteria offers as a foundation for excellence in the welding market, advertising safety and security and dependability in bonded frameworks.

Final Thought

In conclusion, welding evaluation offers as a vital component in maintaining the safety and integrity of welded frameworks. Adherence to market requirements ensures compliance and promotes a culture of high quality within the welding market.

Furthermore, the implementation of welding examination promotes a society of top quality and liability within the welding industry. Ultimately, welding inspection is not just a step-by-step step however a basic component of design honesty and security guarantee, important for the effective implementation of welding jobs throughout different markets.

A comprehensive method to welding inspection includes numerous key procedures that are crucial for guaranteeing weld quality and architectural honesty. These requirements, developed by organizations such as the American Welding Society (AWS) and the American National Requirement Institute (ANSI), offer standards that control the welding process, materials, and assessment procedures.Welding inspectors are charged with verifying compliance with these requirements throughout the welding procedure.